Everything you always wanted to know about the semi-transparent mirror technology (but were afraid to ask)

5. Test of the Sony A99 mirror

|

|

Please Support UsIf you enjoy our reviews and articles, and you want us to continue our work please, support our website by donating through PayPal. The funds are going to be used for paying our editorial team, renting servers, and equipping our testing studio; only that way we will be able to continue providing you interesting content for free. |

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

|

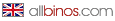

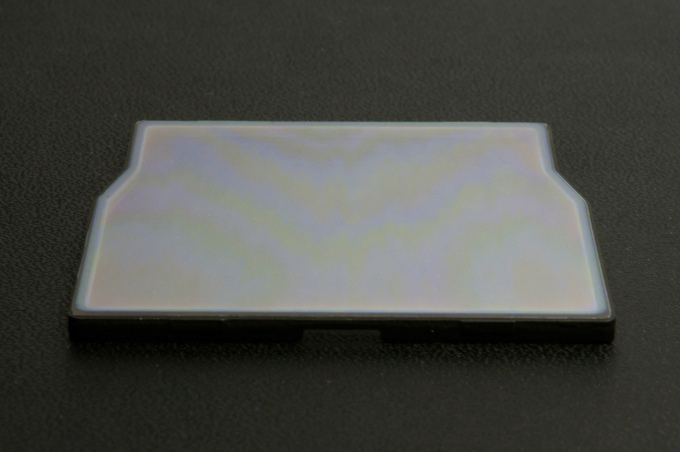

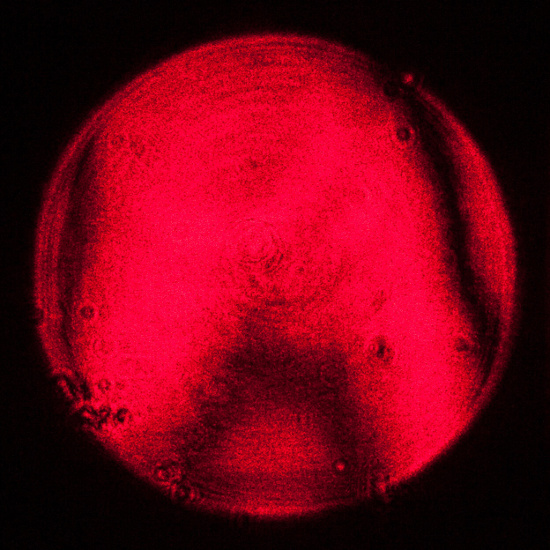

The mirror placed on the interference optical flat test |

|

The mirror looks solid and should withstand several cleanings; its optical quality is good enough to make it a useful tool of the focusing mechanism. Still you should keep in mind the fact you deal here with a piece of very thin film, easy to destroy accidentally.

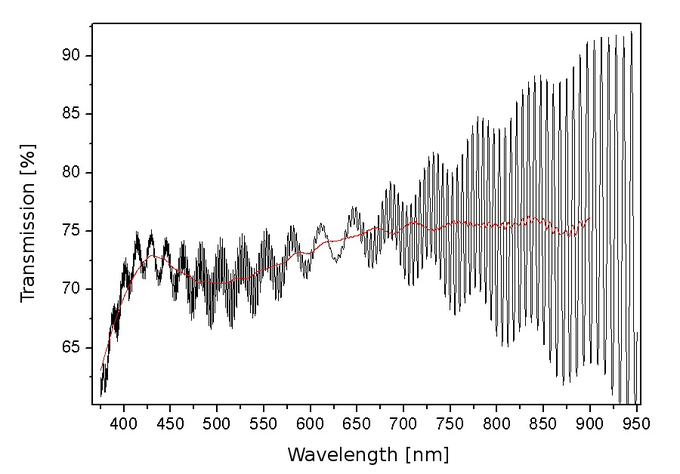

Transmission

During our test we found out that the absorption losses in the mirror are negligible. The amount of reflected light can be presented as the following formula: R=I-T, where I is the intensity of incident light and T - intensity of reflected light. It’s enough to present the results of mirror transmission measurements - let’s start from the perpendicular direction.

Transmission in case of the perpendicular direction |

Still it can be noticed that the light passing through the mirror doesn’t have a neutral colour anymore. The detector gathers the biggest amount of red light, then comes blue and finally green-yellow.

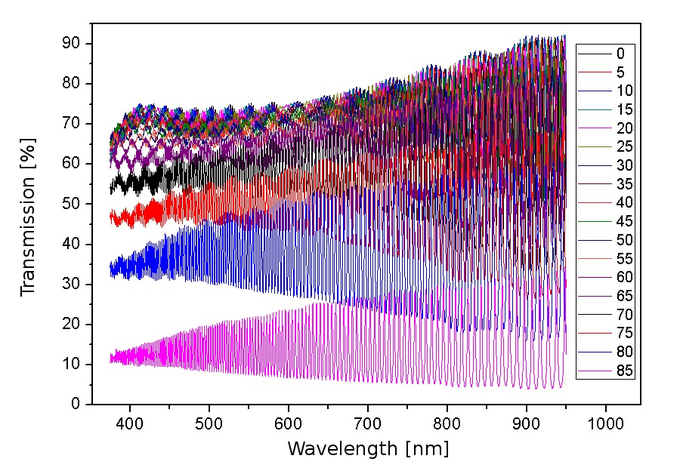

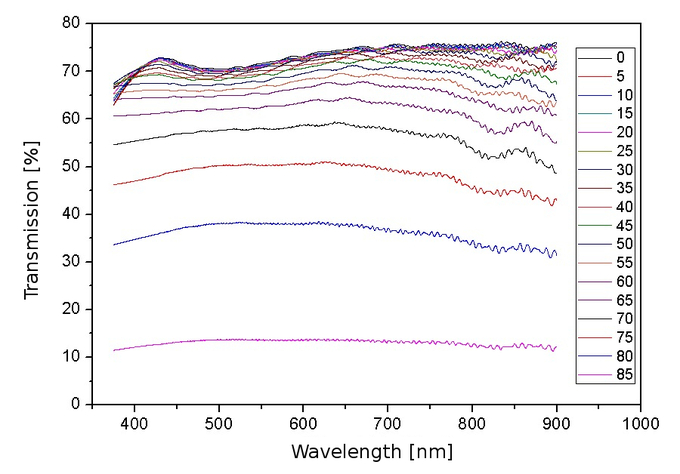

The transmission measurement was performed for different angles of incidence every 5 degrees. The results are presented in the raw form and after averaging out.

Transmission as a function of wavelength for different angles - raw values |

Transmission as a function of wavelength for different angles - averaged values |

The distribution of transmission across the spectrum in the range from 400 to 700 nm so in places where the sensor is most sensitive, is contained in the 5-10% range. The faster the lens the more averaged the final result is. That regularity stems from the fact that image points are created by beams which come from different directions so their angles of incidence are averaged on the mirror.

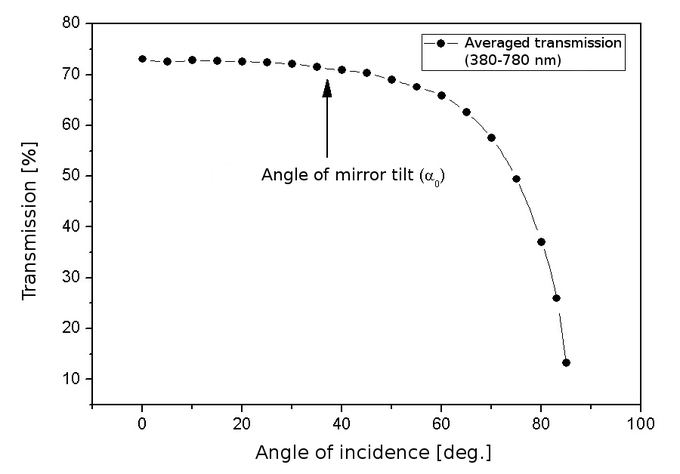

The relationship between the transmission and angle of incidence was determined by using the averaged transmission in the 380-780 nm range so covering the whole visible spectrum.

The relationship between the transmission and angle of incidence |

The mirror let 70-75% of light pass through in a wide range of angles. The brightness loss connected to big angles is noticeable only with fast lenses where it most probably remains negligible anyway due to a mix a lot of beams which fall under different angles. The effect will be averaged like in the case of spectral fringes. For typical lenses the brightness differences can be contained in a 10% range, a value easy to hide permanently in the electronics of the camera.

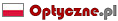

Disturbance of wavefront – interferometric measurement

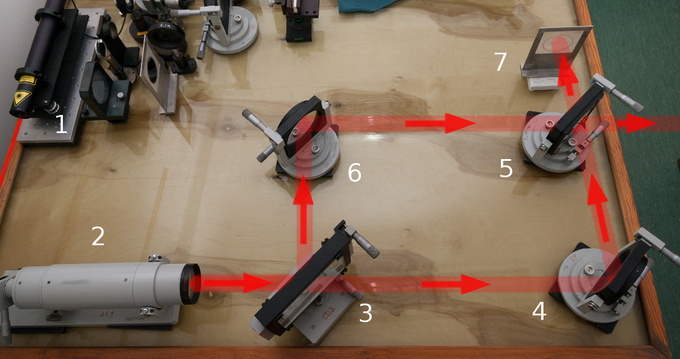

Let’s fire big cannons now. Optical interferometric measurements are among the most precise so in order to assess the perturbations introduced by the mirror to the beam of light passing through it we used the Mach-Zehnder interferometer.

Measurement system: the HeNe laser (1), beam expander (2), beam-splitting mirrors 50:50 (3) and (5), mirrors (4) and (6), screen (7). |

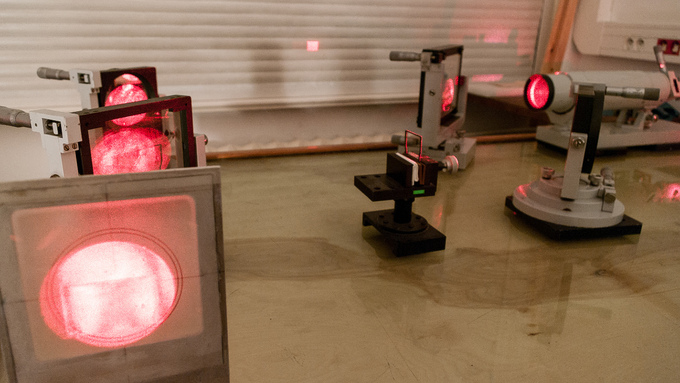

The examined mirror inserted into the optical path |

|

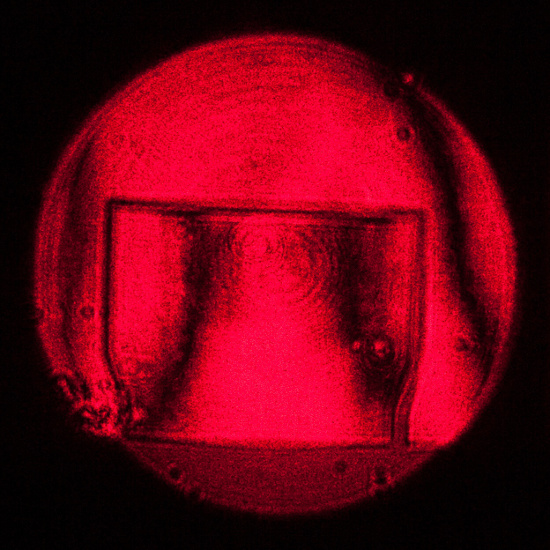

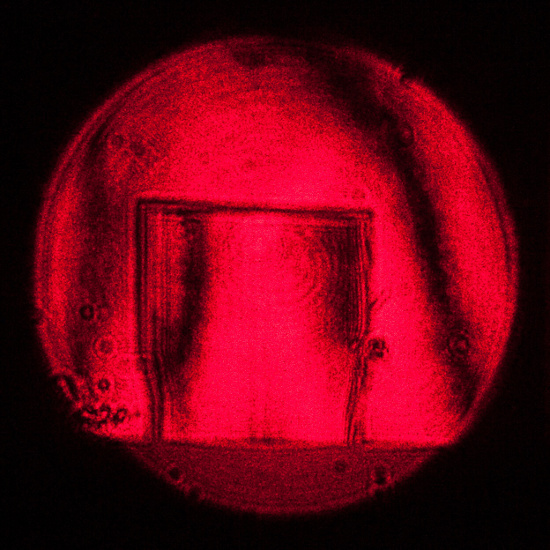

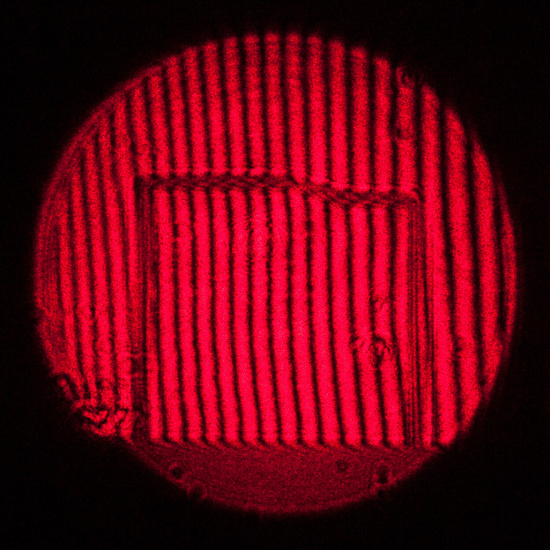

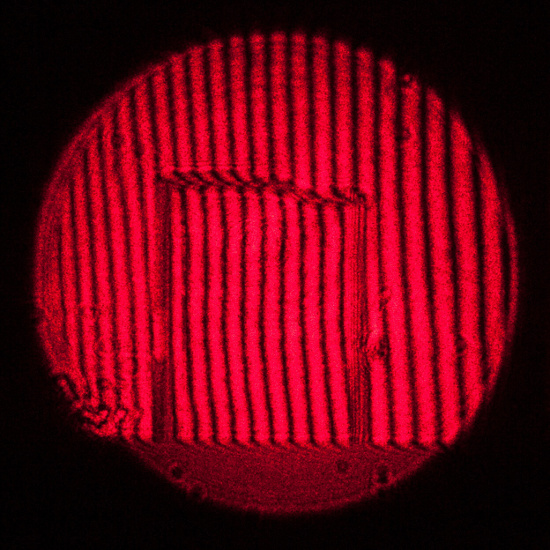

The quantity measurement is easier to carry when you deal with a homogeneous fringes. In order to create the pattern on the output of the interferometer it’s enough you tilt one of the mirrors (6) or (4) vertically or horizontally. The mirrors were tilted by about 2 µm or 0.00002 cm just to show the scale. The mirror was examined for both vertical and horizontal stripes. The reaction of the stripped area to the inserted hand is shown in the next animation.

|

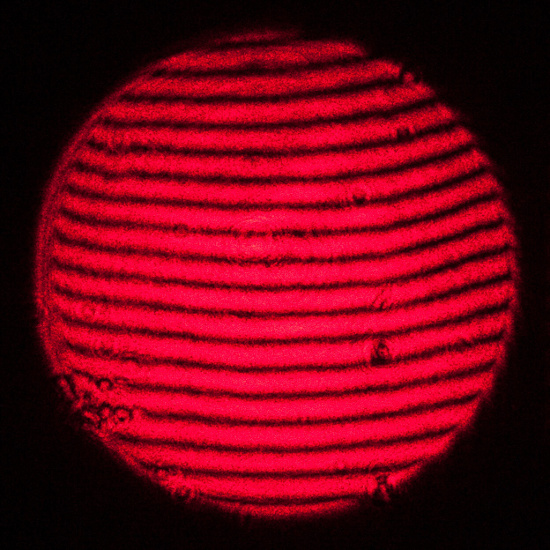

Homogeneous field

|

|

|

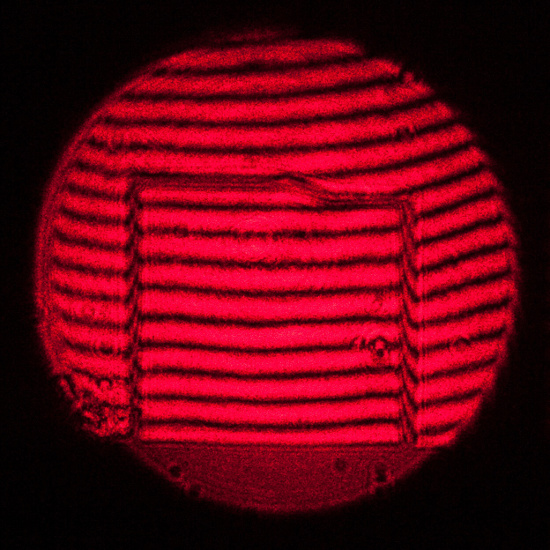

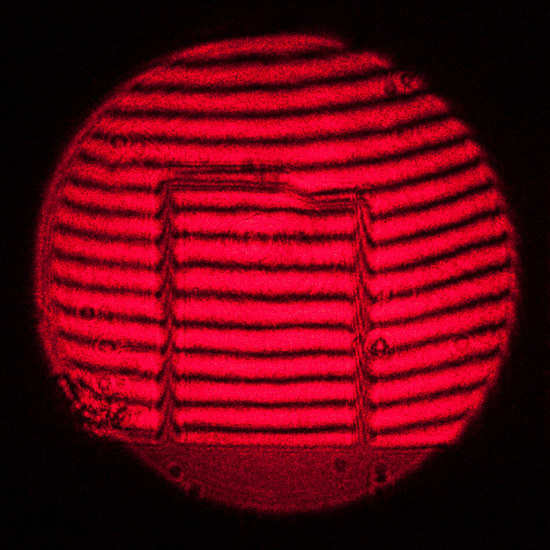

Fringed field (horizontal)

|

|

|

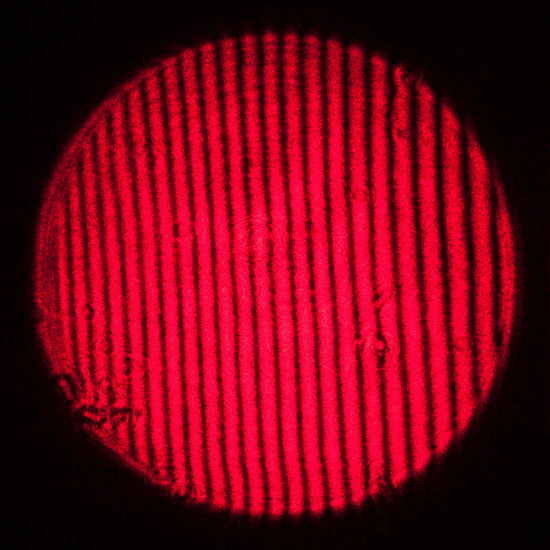

Fringed field (vertical)

|

|

|

The mirror introduces small disturbance of the wavefront – about ¼ - ½ of wavelength. Because of that a fast lens might be not limited by diffraction…if it was limited previously at all. It may be still significant if you can find a lens faster than f/2.8 and with a resolution higher than 200 lp/mm. As there are no local disturbances (high-frequency) f/2.8 lenses and slower won’t lose their resolution in a noticeable or even measurable way.