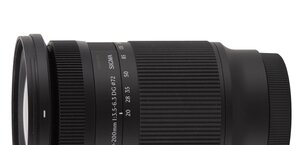

A trip to Sigma lens factory in Aizu

2. Metal processing

In the hall you can find more than a dozen of machines which finish magnesium alloy moulds delivered by an external supplier. During the processing some surfaces of the moulds are polished, cut, drilled, and everything is levelled off with the highest precision demanded by the production of optical instruments.

Please Support UsIf you enjoy our reviews and articles, and you want us to continue our work please, support our website by donating through PayPal. The funds are going to be used for paying our editorial team, renting servers, and equipping our testing studio; only that way we will be able to continue providing you interesting content for free. |

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Even if the whole hall looks more like a locksmith workshop there are a lot of precise measurment tools around. All parts are checked on an ongoing basis; callibrating machines for new working programs needs very precise measurements of first benchmark parts in order to check whether they fit the standards.