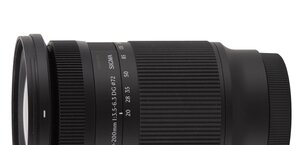

A trip to Sigma lens factory in Aizu

4. Painting

Every part which needs to me marked in any way is manually put into a machine which paints it. So are processed not only tubes but also transparent plastic parts with distance scales or buttons of cameras, like the one shown below with an inscription AEL. After adding appropriate marking the quality of paint is checked – a very painstaking process.

Please Support UsIf you enjoy our reviews and articles, and you want us to continue our work please, support our website by donating through PayPal. The funds are going to be used for paying our editorial team, renting servers, and equipping our testing studio; only that way we will be able to continue providing you interesting content for free. |

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -